EUREKA SYSTEM S.R.L.

Via G. Amendola, 24

31020 Villorba (TV) – Italy

P.I. 03851590269

Home | What is AgiLAB | Automation

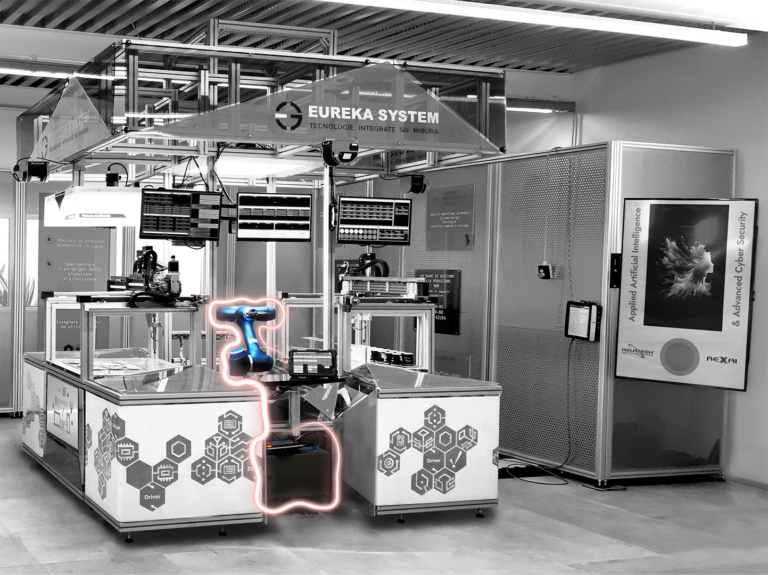

AgiLAB is Eureka System’s demonstration lab, designed to explore and simplify complex processes in the manufacturing world. Through a practical and interactive model, AgiLAB demonstrates the power of digitisation to transform the industry, improving efficiency, flexibility, and competitiveness.

Equipped with an Ignition MES system for production management, AgiLAB integrates different industrial technologies. As a research environment, AgiLAB explores the key topics of Industry 4.0 and Industry 5.0: energy sustainability, process optimisation, digitisation, robotics, and IT/OT integration.

Experience firsthand how AgiLAB makes the future of the digital factory tangible, illustrating that by innovating today, you’re ready to conquer tomorrow’s challenges.

Generative Artificial Intelligence (AI) to simplify human-machine interactions by exploiting natural language.

Artificial Vision to guide robots, used to identify parts’ quantity, position and conformity during Pick & Place operations.

A Doosan cobot for the safe and precise movement of materials between stations.

Cartesian robots for picking materials from warehouses.

Smart sensors for continuous process monitoring.

Advanced functional safety, ensured by laser scanners, emergency buttons and I/O safety nodes, according to industrial safety standards.

In AgiLAB, the generative Artificial Intelligence RexAI redefines the interaction between operators and production systems, transforming communication into an intuitive and natural experience.

Intelligent voice commands: send production orders or information requests using natural language. AI automatically recognises the language and interprets your request.

Simplified data analysis: visualise graphs and production reports with a simple question without writing queries.

With its natural language interface, the MES system allows users to interact effortlessly, just talking, without any technical skills needed.

The Keyence Artificial Vision system integrated into AgiLAB optimises the part-picking and handling operations of one of the two Cartesian robots.

The electronic eye is installed above one of the two raw material warehouses. It allows the pieces to be loaded onto the picking table randomly because the Artificial Vision system communicates the picking coordinates of the individual pieces to the robot.

Real-time identification of quantity, position and orientation of the parts to be picked, dynamically adapting to changes.

Reduction of operational errors: ensures pre-part presence check at Pick & Place.

Flexibility in material management: accelerates supply chain processes, improving synchronisation between warehouse and production.

The Doosan cobot integrated into AgiLAB handles the safe and precise movement of parts between the different production process stations. Its flexibility and ease of programming make it a strategic tool for optimising workflows.

Seamless operation: it transfers materials smoothly between production stages, reducing waiting times and increasing productivity.

Seamless integration with the MES: ensures synchronised order management, adapting in real-time to changes in operation schedules.

Safe collaboration: thanks to its internal safety systems and AgiLAB’s safety barriers, the cobot works alongside operators without risk.

The first Cartesian robot is integrated with the Machine Vision system, while a second Cartesian robot precisely retrieves materials from an organised warehouse using predefined tracking and positioning.

The cartesians’ direct interaction with the Doosan cobot is an advanced example of robot-to-robot coordination that optimises workflows.

Automated and accurate picking: the Cartesian robot retrieves the required parts from the warehouse using an air gripper and ensures the parts’ presence during picking.

Robot-to-robot interaction: the Cartesian robots transfer materials directly to the cobot, reducing intermediate steps.

At AgiLAB, raw material dosing stations are sensorised to ensure accuracy and traceability of manual operations.

Control automation: automatic or manual adjustment of dosing parameters is possible via HMI.

Complete traceability: each manual operation is recorded and associated with the manufactured part to ensure total control of the production order.

Integration with the MES: sensor data are sent to the production management system to optimise operational flows.

AgiLAB is equipped with its own PLC that handles the automation logic of the entire process. This architecture and a distributed I/O system ensure seamless coordination of machinery and software operations.

Real-time production control: the Field Bus system facilitates swift interaction between the various devices.

Scalability and adaptability: AgiLAB’s architecture is designed to grow and change according to needs. Since 2019, it has constantly changed its production process, integrating new components and technologies.

Security management in AgiLAB ensures maximum system uptime while meeting the highest functional safety standards. Every technology and process protects operators, machinery, and data without slowing productivity.

Redundant safety systems: laser scanners, emergency buttons and dedicated I/O nodes create a reliable protection network.

Compliance standards: AgiLAB’s IT/OT architecture also complies with international regulations and standards when it comes to safety.

AgiLAB’s human-machine interfaces (HMIs), developed on the Ignition platform, are designed for maximum usability and accessibility. An intuitive and responsive UI/UX design allows operators and production managers to monitor and manage the production process in real time at every stage.

Multi-device accessibility: compatible with PCs, tablets and touchscreen monitors.

Real-time monitoring ensures immediate supervision of every stage of the production process thanks to customised dashboards.

Centralised control of all technologies integrated in AgiLAB.

Ease of use to minimise learning time and support operators in critical decisions.

AgiLAB’s web-based HMIs combine the power of Ignition with a modern interface that simplifies the complexity of production systems.

AgiLAB’s CAM-Robot, a 6-axis anthropomorphic robot, integrated handling and advanced CNC machining capabilities to optimise the most complex production processes. This demonstration technology was designed to efficiently handle raw materials, semi-finished products, and finished products by directly interfacing with warehouses.

Customised Machining G-code toolpaths: the robot followed CNC programmed toolpaths to perform finishing operations, such as marking and specific customisations on orders.

Flexibility in use: CAM-Robot technology has been designed to be precise and, above all, flexible. It can adapt to various configurations and product variants, making it an ideal solution for a wide range of production processes.

This technology was a concrete example of combining advanced robotics and automation to reduce machining time, improve product quality and optimise material handling.

➔ more information at the official website

Helko is not simply an Autonomous Mobile Robot but a fully customisable industrial handling solution that redefines logistics efficiency. Helko is a Truck Robot, i.e. an autonomously guided mobile robot that acts as a driver to pull trucks or workbenches.

Helko’s flagship feature is its side docking system, a patented, unique and innovative element in the global AMR landscape. This solution offers technical-mechanical features that make Helko flexible and adaptable to many business contexts.

With its advanced technology and unprecedented customisation possibilities, Helko can become the engine of any dynamic and modular production line.

Seamless integration: besides integrating directly with many other business systems, it can be equipped with its own Mission Manager with AI, which optimises logistical activities based on production orders for a seamless workflow.

Active safety: continuously monitors the environment, respecting defined rules and constraints, and can recalculate alternative routes and stops in the event of potential hazards.

Helko is particularly suitable for HMLV (High-Mix, Low-Volume) systems, where product variety and customisation require agile and responsive logistics. With its robust design and advanced autonomous navigation, Helko simplifies the transport of materials, equipment and semi-finished products between different workstations, helping to optimise processes and reduce cycle times.

➔ more information at the official website

Perfect for transportation in articulated industrial environments, Jobot’s Autonomous Mobile Robot facilitated handling activities to and from AgiLAB, practically demonstrating the competitive advantage of AMRs through their ability to operate safely, accurately and without interruption. Designed to operate in complex environments, Jobot improves internal transport efficiency and provides intuitive interaction with the human workforce.

Interactive touchscreen: the transport tray of AgiLAB’s Jobot integrated a touchscreen to allow the recipient to confirm the delivery and complete the mission digitally and securely.

Autonomous navigation without infrastructure: like any AMR, it requires no cabling or physical rails, making it ideal for dynamic environments and reducing installation costs and time.

Safety and adaptability: Jobot recognises its position, detects potentially dangerous situations and adapts its movements in real-time, respecting rules and constraints defined during configuration.

➔ more information at the official site

At AgiLAB, a second Doosan cobot had been integrated and equipped with a 3D structured light vision system designed to perform precise and detailed scans of parts to be picked. This technology was critical for automating certain handling operations that required high accuracy and dynamic interaction between the robot and the environment.

Detailed 3D scans: through structured light, the system accurately captured the shape, position, and geometric features of objects, regardless of the complexity of their surfaces.

Integration with the Doosan cobot: the system communicated with the cobot in real time, allowing it to adapt movements and operations based on the data captured during scanning.

This system combined visual intelligence with the cobot’s operational capability, demonstrating with a practical example how to deal with complex challenges, such as processing non-uniform parts or needing large-scale customization.

3D printing is a key element of the AgiLAB ecosystem because it enables the rapid and customized creation of hardware components and robotic grippers designed for specific applications.

Extreme customization: each holder or gripper at AgiLAB is custom-designed to meet the requirements of manufacturing processes and ensure maximum precision and adaptability to different materials and geometries.

Advanced materials: AgiLAB uses high-performance, strong, lightweight plastic materials to ensure durability and reliability in daily handling operations.

Cost reduction: by eliminating the need for traditional moulds or machining, 3D printing optimizes resources and minimizes waste from an economic perspective.

Robotic grippers made with 3D printing improve interaction with complex materials, ensuring a precise and secure grip even on delicate surfaces and irregular shapes. In addition, leveraging Additive Manufacturing for hardware support of all the various technologies dramatically facilitates the integration of new components, sensors, and tools within the demonstration environment.

AgiLAB is not only a physical demonstration environment but also equipped with a Digital Twin developed with the Emulate 3D platform. It enables virtual replication of every aspect of the system for testing, analysis, and optimization.

With its Digital Twin, AgiLAB is a showcase of Smart Manufacturing and a virtual laboratory for designing, innovating and optimizing cutting-edge industrial solutions. Simulations run on Emulate 3D exploit real physical constraints, kinematics and dynamics, ensuring each test is as close to operational reality as possible.

Advanced simulation: every component and technology in AgiLAB, from robots to handling systems, have been virtualized to test complex operational scenarios in a safe and controlled simulated environment.

Process optimization: through data analysis and experimenting with changes, Digital Twin enables the refinement of workflows and the reduction of bottlenecks.

Predictive design: allows changes or new configurations to be validated without disrupting physical operations, saving time and costs.

Training and collaboration: the Digital Twin also serves as an educational and collaborative tool to visualize processes and results in detail.

EUREKA SYSTEM S.R.L.

Via G. Amendola, 24

31020 Villorba (TV) – Italy

P.I. 03851590269

Eureka System S.r.l. © All rights reserved